Indonesia has a tree that smells good, but this tree is almost partially extinct. Various kinds of animals and plants in Indonesia are almost extinct, so to preserve them must be really careful for good growth.

Our company Alas Gembol with this extinction is still progressing in product sales because our company makes the best use of wood. From small pieces of wood we still make crafts. So that we don’t waste wood and behave extravagantly. As in this mirror, even though it is made of small wood, it can have a high selling and artistic value which is interested in several countries. This is the best selling mirror of the month.

Have you ever imagined? If such a mirror and this little craft decoration is made of quality wood and smells good, then this mirror and this little craft decoration is in your room. Wouldn’t it be aesthetic and look elegant?

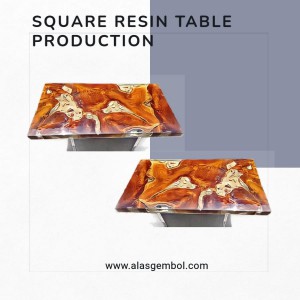

Many variant in Alas Gembol even though it is made of small wood. Example picture like this.

Here we will discuss what fragrant trees can be used as furniture in Indonesia, let’s see:

1. Sandalwood Tree

This tree is famous for having a very fragrant aroma with dazzling characteristics. This tree used to be easy to find but now it is not easy to find it. In addition to being rare, this tree produces wood which is very expensive because it has a distinctive fragrant aroma. So the price of wood from this tree is very expensive. However, for planting on this tree, some people preserve it and make it for sale so that we can use it as crafts and furniture that has high art. Why do planting for business? because the wood from this tree is famous for being upscale or luxurious.

2. Agarwood tree

This tree has a very fragrant sap, the wood of this tree smells good, is very strong, hard and durable. This tree can be found in the forests of Kalimantan. The wood from this tree is very salable in the world market along with its furniture. Because the quality of the wood is very good. But the wood from this tree is very expensive. Most people call this tree is from heaven. The sap of this tree is very fragrant so it is widely used as cosmetics, perfume, and medicine as well.

3. Cinnamon Tree

This tree can be found and comes from Central Java, Indonesia, this tree is very fragrant, usually used for cooking spices, and in addition to medicine. But don’t get me wrong, the wood from this tree is also used by wood craftsmen to make wood crafts, usually as wall decoration and home interiors.

4. Suren Tree

This tree can be found in Java, Sumatra and Kalimantan. The wood of this tree smells good and has a sandalwood-like quality. It is a tree that is liked by the community, because the wood from this tree is easy to find and of good quality to be made into furniture and wood crafts.

4. Camphor Tree

Camphor trees are often found in Sumatra and Kalimantan. This wood is very hard so that carpenters usually use it as raw material for windows, frames, doors, which do not have a high complexity because if there are carvings in the manufacture, carpenters or craftsmen rarely recommend wood from this tree. This wood was chosen because it produces a traditional scent, namely the smell of lime which is very fragrant when the tree is cut. However, the use of wood from this tree is not recommended as furniture in your bedroom. Indeed, the aroma of this wood can repel insects, but this aroma can cause some people allergies and cause irritation.