There are two types of preservation for wood that you will make into furniture, including:

1. Permanent Preservation

If you use permanent preservation, then you have to think carefully first, because this type of wood preservation should not be processed again. This type of preservation aims to withstand all the wood destroying factors for a very long time. You must know that after this type of preservation is carried out, the wood should not be sawed, planed, drilled, sanded, etc. Because if the wood is reprocessed, you will also carry out re-preservation as before, even though you only do a little activity on the permanently preserved wood. Because this is to prevent the wood from opening its pores. So it can last a long time.

Keep in mind that we must choose preservatives that do not interfere with human health, because health is indeed important, if you make wood for your furniture then choose a preservative that does not affect the paint, shape, polish, and does not change the color of the wood.

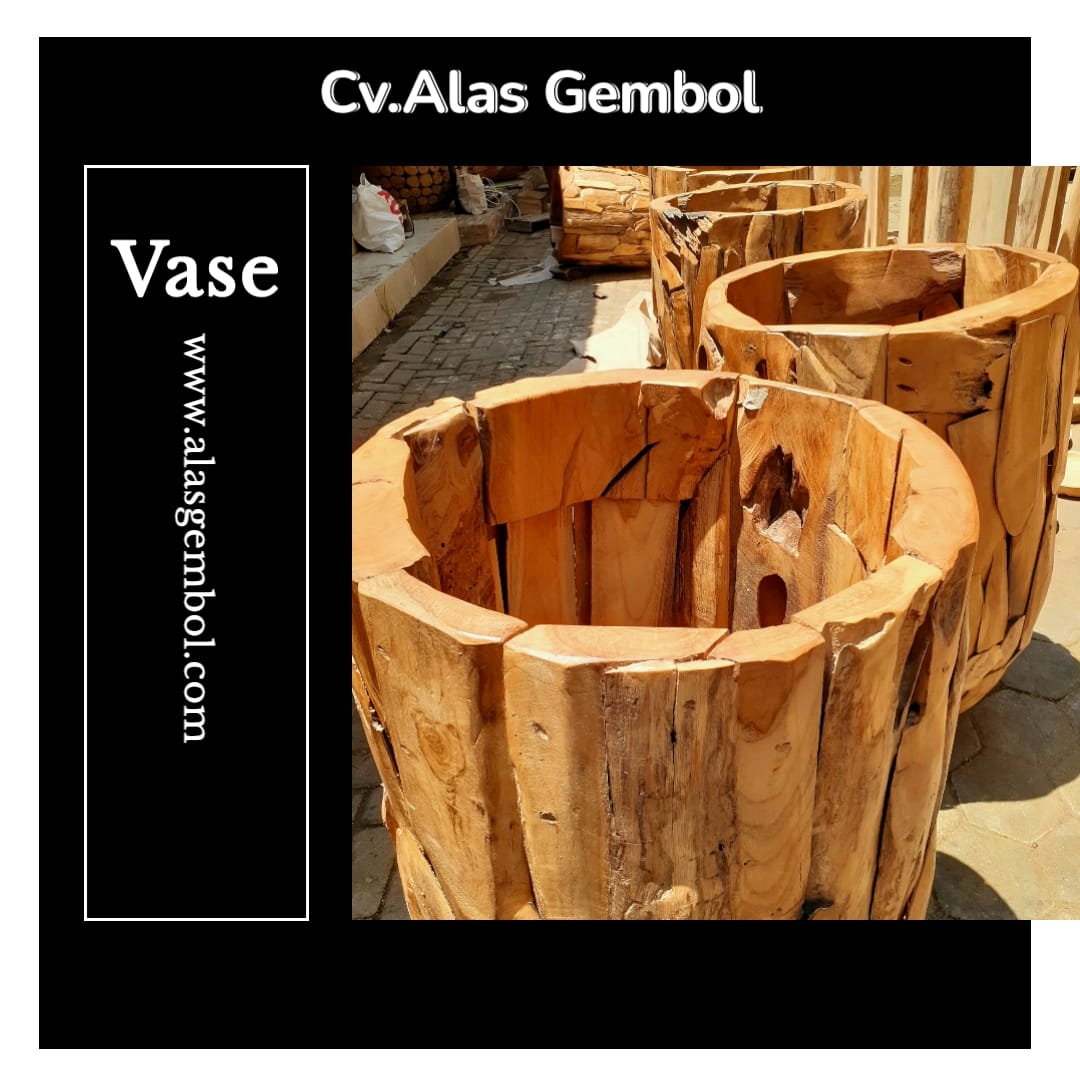

This is one of our products, which performs a permanent preservation technique, And beside it is the result of smearing.

Preservatives that are often used are materials that contain arsenic salts, because these ingredients can repel insect attacks that are powerful and in large quantities.

There are also times when wood which usually produces water really needs to use preservatives that do not fade and are quite toxic to fungi, use carbolineum and creosote types which have high levels of toxicity, this is to avoid attacks from various living creatures or pests who like moisture.

2. Remanent or Temporary Preservation

Did you know that there is also temporary preservation, this preservation is done to avoid attacks such as rotting fungi, dew that causes moisture, and other wood destroyers, if the wood after being cut or cut from the forest, then most of the wood must be damp and wet, especially after sawing then from this case, this preservation is used. This preservation also avoids insects, usually the ingredients used are Gammexane, Sodium Penthachlor Phenol (NaPCP), Borax, etc. It should be noted that this type of preservation is temporary, so you must regularly and diligently research and see your furniture in the short term. To avoid damage.